Why the Size of Steel is Important in Fire Proofing: Not All Steel is Created Equal

Fireproofing steel is vitally important in a construction project. Protection of the structural elements is not only important in allowing people to escape a burning building, but also to allow emergency crews to work quickly and safely in and around the building.

When steel is exposed to intense heat it loses strength rapidly. This severely compromises the structural integrity of a building during a fire. The collapse of steel members in these instances can make it harder for people to escape during an emergency, and increase the intensity of building damage.

However, not all structural steel is created equally. Fireproofing can (and does) vary based on the size of a steel member. This article covers why the size of the steel plays an important role, and how to establish the required thickness of an intumescent coating on steel.

Table of Contents:

During a building fire, different steel sections can heat at different rates. The measure of mass (weight of the structural steel in comparison to the amount of steel exposed to fire) dictates how quickly the steel heats up, where steel that is less massive heats more quickly than steel with greater mass. This is important to consider when fireproofing steel and trying to establish the necessary amount of intumescent applied to a specific steel section.

Several calculations are used when considering the massivity of steel; Hp/A, W/D, and A/P ratio being the most common. In the United States, W/D ratio is utilized for Wide Flange and miscellaneous steel shapes, whereas A/P ratio is employed for Hollow Steel Sections (HSS).

Hp/A, which is known as “Section Factor”, can be applied as a calculation for all steel profiles, and is determined by dividing the perimeter of a section by its cross-sectional area. These calculations are available for all standard steel profiles, typically from the manufacturer, or through engineering resources.

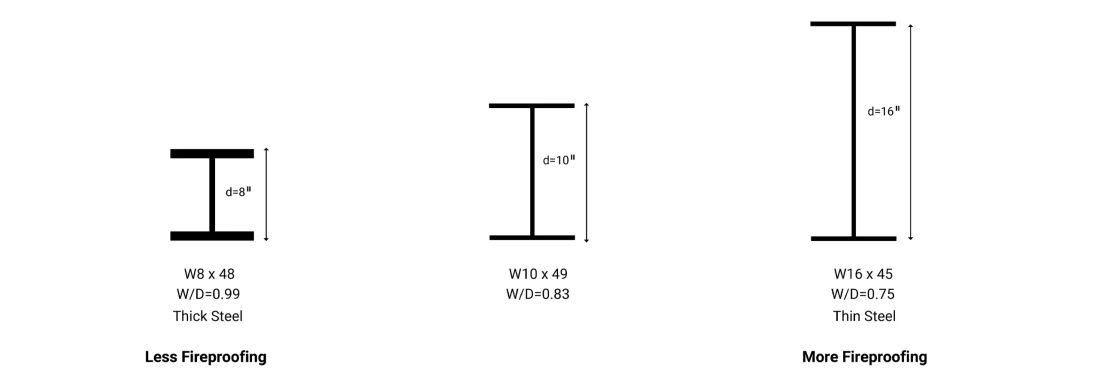

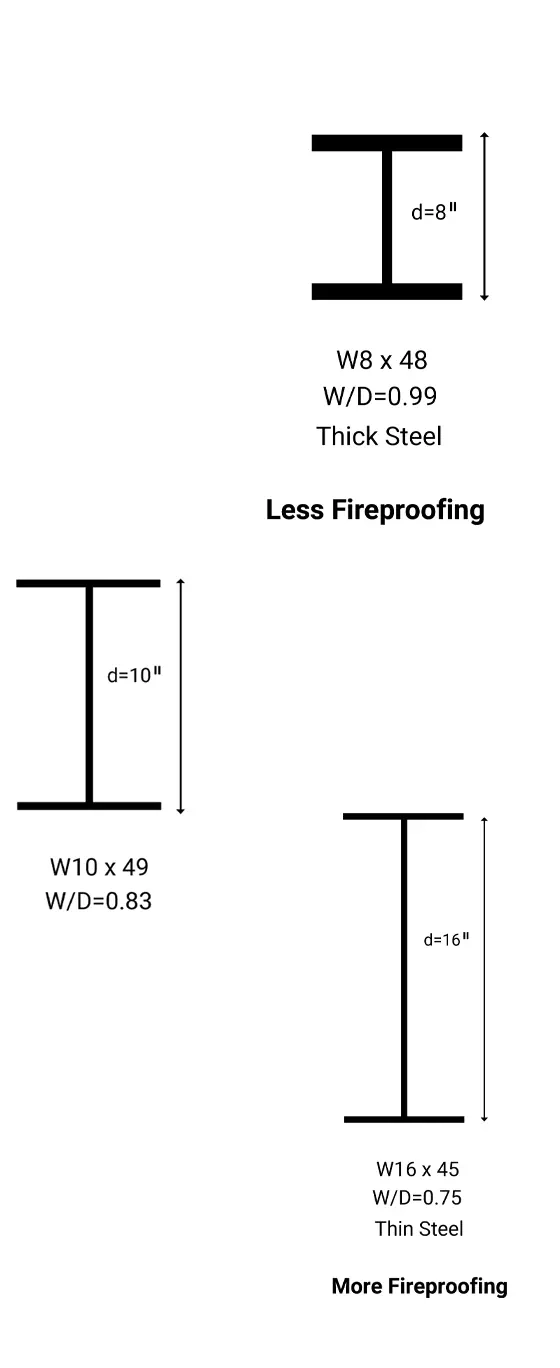

As a general rule thicker steel members will heat at a slower rate than thinner steel members, and therefore will require a lesser dry film thickness. As such, thinner steel members will generally require greater fire protection than thicker ones. This is demonstrated below, where pieces of steel with the same weight per linear foot, but different cross sectional dimensions, are shown to have different W/D ratios.

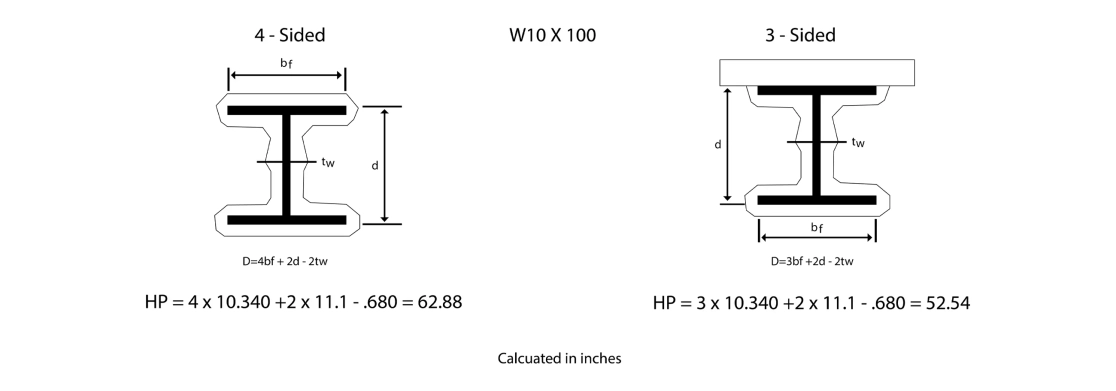

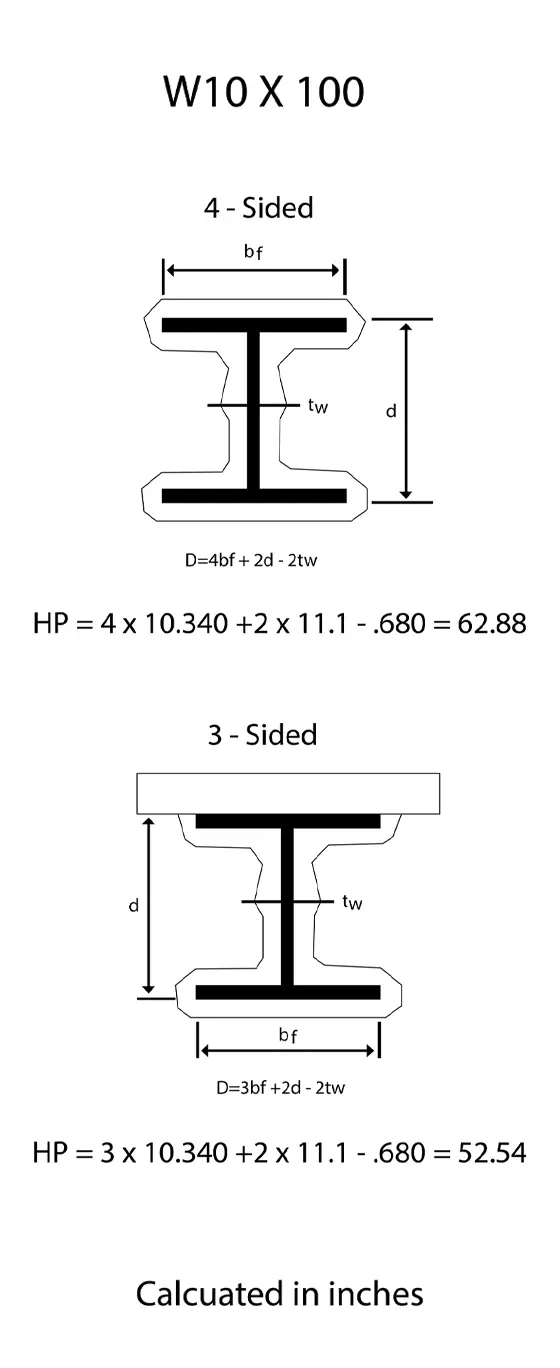

Another important factor to consider is the orientation and exposure of the steel. The same piece of steel will have a different W/D ratio, or Hp/A, when used as a 4 sided column vs as a 3 sided beam. This is because the heated perimeter (or area of the steel exposed to a fire) changes depending upon the orientation.

Generally, as the heated perimeter decreases, the rateability of the steel increases, because less of the steel is exposed to fire. This relationship is demonstrated below, where the same W10x100 steel member is shown to have two different section factors for 4 sided column and 3 sided beam exposures.

Understanding these calculations can go a long way in understanding how intumescent coating thicknesses are specified. As the W/D ratio and A/P ratio increase, the amount of intumescent coating required decreases. Hp/A is inversely related: as Hp/A increases, so does the required coating thickness.

Intumescent paint is a form of fireproofing, a specially formulated coating that expands when exposed to intense levels of heat during a fire. Intumescent paints can be used to protect a variety of popular construction substrates including steel, gypsum, and wood, helping builders meet fire safety standards in construction projects.

When exposed to a fire, an object coated in intumescent paint can be protected for an extended period of time. As the coating heats under flame it expands to provide an insulating membrane for the structural unit underneath, preserving the structural integrity of the substrate for an extended period of time, and preserving a building, potentially giving individuals inside more time to escape, and first responders more time to put out the fire.

How do you establish the required thickness of intumescent paint on steel? There are several factors to consider when establishing the required thickness of intumescent paint. Different projects may have different requirements, and it is important to communicate with building officials when moving forward.

To establish the required thickness of intumescent paint on steel, the following information is required:

- Standard of approval: ex. ASTM E-119 (full-scale)

- Fire resistance period: ex. 60 minutes

- Structural section: ex. Wide Flange

- Degree of exposure: ex. 4 sided column/3 sided beam

- Steel member: ex. W10 x 49

- Steel section factor: ex. (W/D or Hp/A)

Using these details a supplier can determine the required dry film thickness (DFT) from a fire test that has an IAS accreditation for fire testing full scale structural members.

Determine the amount of intumescent coating you need for your steel members with our steel coverage calculator.

FlameOFF Coatings are manufacturers of state of the art fire proof coatings. Our intumescent paint provides up to 2 hours of fire protection on steel. FlameOFF Fire Barrier Paint guarantees quality with a smooth egg shell finish, and immense testing from third party labs like UL and ICC to guarantee effectiveness.

Our technical sales team offers great support in answering questions pertaining to fireproofing. Work with us and we will help you understand the factor of size in the amount of product you will require for a project.

Find more useful fireproofing resources here.