Applying Fire Rated Intumescent Paint on Wood

Fires occurring in commercial buildings are one of the main concerns when designing and constructing a building that is meant to be safe. The chosen construction materials will have a fundamental impact on a building’s susceptibility to fire, as well as on the fire protection requirements that the building will have to meet.

Wood is a combustible material, being a natural support for flames. One of the main goals of building and fire codes is to limit the spread of fire and protect nearby buildings if a fire occurs. For example, buildings that are in close proximity of each other must ensure that wood panel structures, if they exist, are protected by a fire retardant system that is approved within the jurisdiction where the building is located.

Fire retardant and intumescent paint is applied to wood and timber structures to slow down the spread of fire and it is an effective way to delay or avoid the collapse of a building in the case of a fire. In response to heat, fire retardant paint produces a flame-damping gas that limits the spread of flames across the surface. Flame retardant paint is not used on wood structure as often as intumescent paint because it has limited insulating properties.

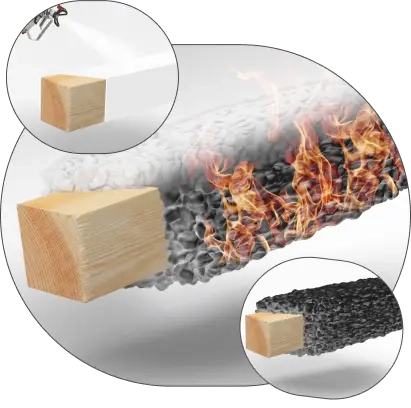

Intumescent paint reacts to high temperatures by swelling for up to 50 times the original thickness of the paint and insulating the wood structure, effectively increasing the burn through time to 30-60 minutes. Intumescent paint does not make a wood structure fireproof yet it slows down the spread of fire thanks to its coating elements, which expand in response to high temperatures, creating a layer of char that insulates the substrate. In other words, while an intumescent coating applied to wood won’t stop a fire, it will significantly reduce the risk of premature structure failure. Additionally, some intumescent products can suppress the emission of gases produced by the combustion of wood. By decreasing smoke development, intumescent coatings slow the build-up of gases and reduce the production of a flash over-which is a type of explosion produced by gas mixture ignition.

Try the FlameOFF Coatings steel calculator to get an idea of the approximate amount of product needed for your projects. It is the guide you need to minimize the guesswork in your projects.

Steel Coverage CalculatorYou can achieve 1 hour-fire rating with a dry film thickness (DFT) of 30 mils that provides a coverage rate of 37 sq ft/gal. Achieving Class A rating, on the other hand, requires 10 mils DFT and provides a coverage rate of 113 sq ft/gal.

Technical Data

FlameOFF® intumescent coatings provide the installer an easier application of the intumescent coating and offer design professionals many benefits.

Listings

The performance criteria as set out in a building code are clear and unambiguous, and need to be tested by an independent third party. Our tests are completed by national accredited testing laboratories. Their unbiased results are the basis for our certification listings.

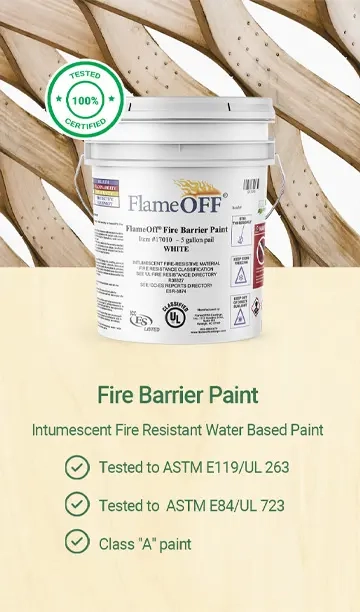

FlameOFF® Fire Barrier Paint has been tested to ASTM E119/UL 263 and ASTM E84/UL 723 Fire Endurance standards to meet the requirements set forth by IBC/NFPA Building Codes. Our product is ICC Listed and UL Classified and can be found in the ICC Listing Directory and UL Product iQ, and below. Please contact FlameOFF® Coatings Technical Team to receive individual test reports conducted to ASTM E119/UL 263 and ASTM E84/UL 723 test standards for all substrates.

| Program | Standard | Details | Record | Design/Listing |

|---|---|---|---|---|

| ASTM E119 UL 263 CAN ULC-S101 | Wide Flange and Hollow Steel Sections Gypsum | ESR-3874 | ESL-1191 | |

| ASTM E84 UL 723 CAN ULC-S102 | Gypsum Wood | ESL-1192 | ||

| UL 263 CAN ULC-S101 | Wide Flange and Hollow Steel Sections Gypsum | CDWZ.R38327 CDWZ7.R38327 | BXUV.N56 BXUV.Y658 BXUV.W310 | |

| UL 2818 | Emissions Testing | 339065-420 |

While gypsum sheathings will provide better protection compared to coated panels, FlameOFF® Fire Barrier paint offers a clear advantage when it is necessary to apply a coating product to custom or irregular wood areas and can be used to upgrade the hour fire rating of wood substrate.

FlameOFF® Fire Barrier paint can also be a good option to increase a wood structure’s fire rating as long as natural wood look is not relevant.

Another advantage of the product is its user-friendliness; as it can be applied on wood with a brush or a spray machine.

The intumescent paint can be topcoated with latex or acrylic paints in order to obtain a specific color.

It is worth noting that there are currently no intumescent coatings that can provide a 2 hour fire rating on wood by itself. Intumescent paint, like other coatings, works together with the substrate in order to limit the spread of fire, and the results will be more modest when the substrate is less resistant to heat, which is often the case with wood materials. Some wood types, such as heavy timber, have a substantial rating on their own and may result in >1 hr rating with the addition of intumescent paint.

Timber provides superior fire protection compared to other wood substrates by forming a substantial char layer once the wood begins to burn. The char layer provides insulation to the core of the wood section, delaying the collapse of a structure. This means wood members that are designed in a way that provides sufficient cross section of wood can sustain the loads for a longer duration of fire exposure. Chapter 1 of the National Design Specification (NDS) for Wood Construction provides instructions on how to calculate the fire resistance of exposed wood members. For questions about rating wood substrates for 2 hours, please contact our technical team.

COMMERCIAL

INDUSTRIAL

RESIDENTAL