There is no denying the complexity of proper fire rating. The process can be costly and time consuming, demanding meticulous attention to detail. Construction professionals entrusted with this responsibility must navigate a labyrinth of considerations, from materials and application methods to legal regulations, aesthetic preferences, and more.

Not only is it challenging to juggle all of the varying stipulations of building codes, but different methods of fireproofing offer various pros and cons. Deciding on the most suitable approach for a project is far from straightforward.

Amidst tight deadlines and budget constraints, the pressure to complete projects efficiently can lead professionals to seek shortcuts.

When offered what appears to be the easy way out by an engineering judgment, it might be tempting to accept and move on. However, it's imperative to recognize that engineering judgments should not be treated as a "get out of jail free" card.

Cutting corners in fireproofing can have catastrophic consequences. Legal ramifications and substantial material losses are just the beginning—worst-case scenarios can result in the loss of human lives. Therefore, it's essential to understand the nuances and implications of fireproofing decisions, read on to learn more about:

Building professionals on a crunch might be concerned with the required coatings necessary to properly fire rate a substrate in their design. In an attempt to save time and money, they might turn to an engineering judgment that suggests using fewer coatings of a product to save time and resources. However, this approach compromises the safety of the entire building.

An engineering judgment is not a workaround for meeting compliance to properly fire rate a building. There is a misconception that an engineering judgment is an all-clear to cut corners on fireproofing.

Construction professionals might be attempting to bypass the recommended DFT (Dry Film Thickness) requirements of an intumescent paint. Fewer coatings mean less paint application, fewer gallons required, and more time and resources saved.

Failing to meet DFT requirements compromises the substrate's ability to withstand heat during an emergency, potentially leading to quicker structural compromise. Each layer of a coating provides vital minutes of protection under heat.

To achieve reliable fireproofing, there's no substitute for the findings of a product's official testing.

The presence of an engineering judgment is not sufficient to meet safety standards. The only trustworthy data comes from the tests supported by product listings and documented on official data sheets.

These specifications should be followed diligently when taking steps to fireproof a building.

In real-time during a fire each layer of an intumescent coating on a steel membrane represents minutes of protection under heat. Failing to apply the required DFT to rate a substrate properly will lead to more extreme hazards in the case of an emergency, leading to quicker compromise to structural integrity during an active fire.

A building professional main priority should be the long-term safety of building occupants and preserving the structural integrity of a building in the case of an emergency. When it comes to fire safety, code compliance is non negotiable.

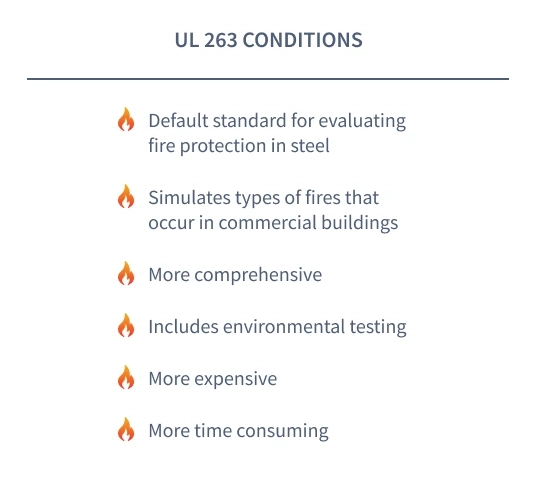

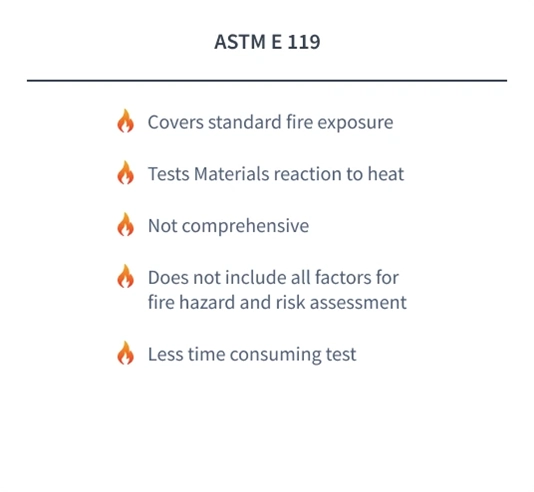

Different tests and listings promise different levels of protection for a coated assembly. UL 263 and ASTM E 119 are two common standards, with UL 263 offering a more comprehensive assessment due to its inclusion of environmental tests.

UL 263 includes rigorous environmental and weatherization tests, providing insights into a coating's performance under challenging conditions. These conditions prove a product’s longevity under a range of difficult environmental factors. This is something the ASTM E 119 test does not cover, making UL 263 more reliable, yet harder to attain.

The exposure of a coating to more intense environmental conditions is vital as some products may not survive more humid conditions, or other alternatives that might compromise the safety of a building should a fire break out.

The UL 236 conditions cover three different kinds of spaces: interior condition, interior general purpose, and exterior. As previously established, ASTM E 119 testing does not cover any forms of weatherization testing.

Testing the full range of environmental conditions is the only way to confirm that a coating will be able to protect a building under a range of more extreme conditions. It is important to understand which conditions a coating did and did not meet during testing prior to application. For instance, some coatings might be applicable for all three conditions while others might only cover two or one.

A coating operating to protect a fully internal building with a standard HVAC system, may not perform as adequately for a building that has become semi-exposed to the environment (perhaps due to a natural disaster like a hurricane that might expose a substrate to new environmental conditions).

The presence of proper testing and listings is the only way to confirm this type of very specific performance. An engineering judgment will not absolve building professionals trying to rush fireproofing of this responsibility.

Different types of steel require different levels of protection. Learn more

Imagining worst-case scenarios underscores the gravity of relying on engineering judgments as shortcuts. Using such judgments in an attempt to bypass proper coding compliance can lead to disastrous outcomes, placing property and lives at risk

Trying to meet deadlines and get the job done within budget is challenging. A construction professional’s priorities may not encapsulate the long-term picture. It might be tempting to go around proper coding compliance with an engineering judgment that claims fewer coatings of an intumescent are enough to provide the right level of fire protection.

However, if an accident were to occur and a fire broke out in a building that failed to meet the right level of protection, the consequences might be catastrophic. The responsibility for any property damage and lost lives belongs to the professionals who rushed the fireproofing.

The only reliable application guidelines are those mandated by the listings of fire safety products. Follow the instructions provided by the product specifications and the manufacturer’s technical support team to ensure the proper execution of this critical safety feature.

The prudent approach is to adhere to the application guidelines of product listings. Technical support and manufacturer-provided data sheets offer valuable guidance to ensure the correct execution of fireproofing.

Do not cut corners on the application of intumescent paint. Do not rely on engineering judgments as a valid route to properly fire rate a construction project.

Making sure your project is fully compliant is easy when you partner with reliable manufacturers who prioritize honesty over making the sale. Human lives are at stake and FlameOFF Coatings takes this responsibility seriously. See FlameOFF Certificate of Compliance

Our technical support team is willing to work closely with construction professionals to ensure that they convey realistic projections for DFT/WFT necessary for the proper rating of the substrates incorporated in a project.

Learn more about Fire Barrier Paint as an option for properly fire rating your building. Talk with our informed technical sales support team with any questions or concerns.