Finish Rating on Drywall

Navigating fireproofing and fire ratings can be difficult. Especially when juggling so many different variables, finish ratings, different types of drywalls, and the race to get a construction project up to code within a reasonable amount of time.

This article explores a deeper breakdown of finish ratings, including the definition of industry terms, differentiations between types of drywall, and alternate methods to maximize the fire rating of building materials.

Read on and learn:

ASTM E119 fire endurance ratings are considered the standard for testing how long a wall or floor/ceiling can safely contain a fire. In the United States, most residential and commercial buildings require a 1 or 2 hour fire resistance rating by this standard.

During testing, there are several factors that measure performance including, but not limited to; the temperature on the back side of the assembly, flame through, ability to pass a hose stream test, and load applied, if required.

When we consider a successful test, it is one that is limited to a temperature rise above ambient of no more than 325F at any individual thermocouple, or an average rise of no more than 250F above ambient across all thermocouples, on the back side of the wall or floor/ceiling assembly. This is the side that is not exposed to the furnace for testing.

And how does the finish rating differ from fire endurance rating?

A finish rating is best understood as the amount of time it takes for the stud on the back side of the fire side of the drywall to reach a maximum limiting temperature. This is defined as 325F (180C) above ambient temperature at any 1 thermocouple, or an average rise in temperature of 250F (140C) across all thermocouples. Basically, the same performance standard we discussed above, except we are measuring it on only the “fire side” face of the wall, not the entire wall assembly.

To put it simply, this test measures how long it takes for the back side of the drywall to “heat up” to an allowable threshold. This rating is important as it allows us to directly compare the performance of different drywall products.

If you thought that was a mouthful- you're right! Think of it this way: the unexposed side of the drywall that is facing the furnace. The other side of this sheet of drywall is directly exposed to fire!

On average a regular piece of ⅝” Type X gypsum has a finish rating of 18-26 minutes. This rating will vary depending on the manufacturer. This information is important, because it contributes to how the calculated fire resistance rating is determined (as in Section 722.6 of the Building Code).

By comparison, ½” regular drywall is not typically provided a finish rating, as it is considered not to be a rated product at all.

There are two primary forms of drywall which are specifically designed to offer fire resistance, Type X and Type C. When it comes to understanding the process of fire-rating gypsum in projects it is helpful to differentiate between these two materials.

The categories of fire rated gypsum board are determined by how well they hold up under exposure to fire. Most fire rated materials will outlast standard ½” sheetrock by at least 45 minutes in a fire, if not longer.

The difference between Type X drywall and Type C drywall is present in both the thickness of the product and the composition. Type X drywall is ⅝” thick, while Type C drywall is available in both ½” and ⅝” thicknesses. Type C tends to contain more fiberglass in its composition making it more fire resistant than Type X drywall.

A common occurrence in fireproofing projects happens when a wall is anticipated to include one type of drywall but either the material cannot be sourced, or the contractor accidentally installed the wrong type of sheetrock. In other projects, the drywall may be an existing construction. In all cases, the fire endurance rating needs to be increased to comply with the code requirements for that construction type.

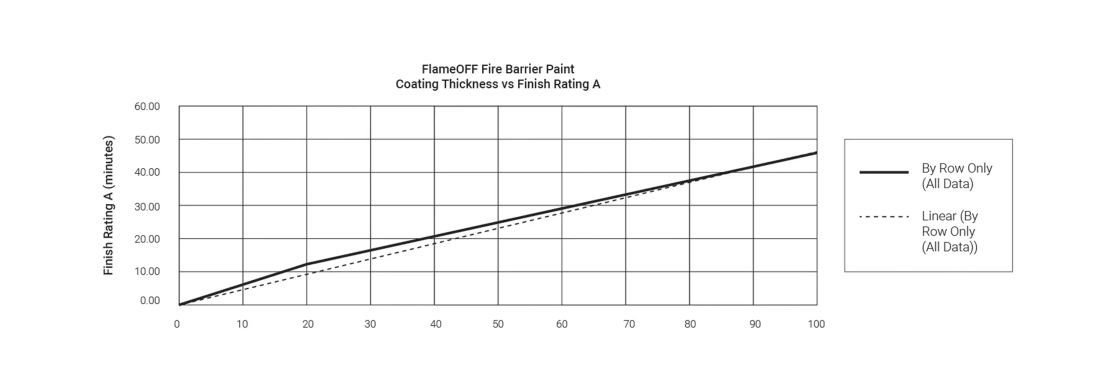

This is where intumescent paint comes in! By adding intumescent paint, additional time can be gained on the calculated fire resistance rating of drywall. Below, you will see a table that charts the increase in finish rating achieved by adding Fire Barrier Paint, at different thicknesses, to the fire side face of the drywall.

Data pulled from ICC report: Data Evaluation of ⅝” Gypsum Wallboard (UL Type ULIX) with FlameOFF Fire Barrier Paint thickness versus finish rating Data (FCI103020-40 R1)

A proper fire rating is achievable with the right materials. Intumescent paint is incredibly beneficial in getting the drywall in construction projects up to code. An intumescent coating is an efficient and eco-friendly form of fire protection that can grant up to 2 hours of fire protection on diverse substrates including drywall.

By applying an intumescent paint on drywall the fire rating is significantly increased, eliminating the need to tear down existing layers or hang additional ones.

If interior aesthetics are a concern, FlameOFF Fire Barrier paint offers a smooth latex like finish along with quality fire protection. This quality white egg-shell smooth coating will bring your projects up to code without compromising on aesthetics.

Contact us today with any questions on increasing the finish rating on drywall!