Fireproofing Methods For Wood

Wood continues to be one of the most popular substrates in modern construction, however, it is a highly flammable material. In order to safely incorporate wood in a project, you will have to comply with certain fire standards to ensure a secure level of fire safety for a structure.

Although it is impossible to completely fireproof wood, there are several approaches to increasing the safety of a wood assembly in a construction project. Read to learn about these strategies, how to determine wood’s fire resistance and several FlameOFF Coatings specific solutions.

How do you determine the performance of wood during a fire, and how does it impact human safety? What performance ratings are important, and how does that translate to life-safety?

As wood is a substrate with highly flammable properties, it is critically important to properly test and maintain safety on wood finishes and structures in construction. Some wood is pretreated during manufacturing. This wood is typically labeled as Fire Retardant Treated Wood (FRTW). But what does FRTW really mean, in terms of rating? If you are not using FRTW, how does your wood product compare, and how can you make it compliant?

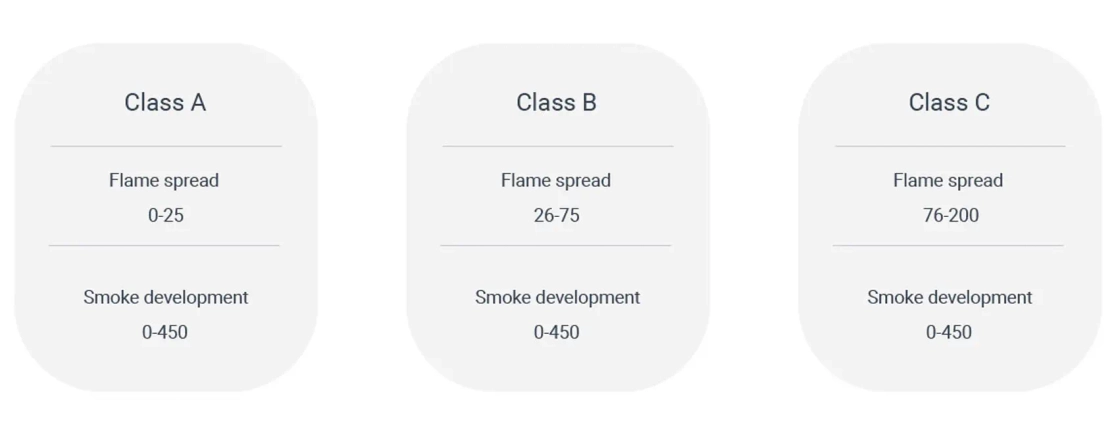

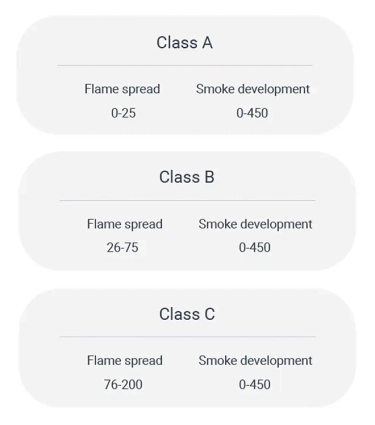

In order to qualify as FRTW, the IBC requires that both the flame spread and smoke development indexes of the substrate are measured. This means when an ignition source is present, the distance of flame spread is tracked, as well as the amount of smoke generated. These qualities are important because they play a big role in allowing people to safely evacuate a building at the onset of a fire.

The test to measure flame spread and smoke development is known as the ASTM E84 Test (also known as UL 723 and CAN ULC S102). It is a 10 minute steiner tunnel test that assesses horizontal flame spread and smoke development by observing the substrate’s behavior under exposure to fire. The test measures how quickly the flame travels across the surface of the wood.

Meanwhile, a test known as ASTM E2768 is virtually the same test as ASTM E84 however it is extended to a 30 minute burn period. This test is also known as E84 “Extended” and is the typical standard requirement for FRTW.

- Flame spread: The standard for assessing flame spread exists on an index. During an ASTM E84 test the rate of flame spread as well as the distance of flame traveled would be incorporated into the conclusive rating of a substrate. This is measured based on a scale that ranges from 0-200. Generally, a smaller index number is more desirable.

- Smoke development: Smoke inhalation can be a lethal side effect of a building fire. In the case of fire safety, the lower the better, but anything under 450 is acceptable for E84.

The results are shown in this table below:

Performance results of this test are measured in comparison to a raw wood sample, which typically has a Class B or C rating. Interior finishes usually require a Class A rating.

For example, Class C woods usually include yellow birch, douglas-fir, white pine, as well as lodgepole and ponderosa pine, maple, red and white oak, OSB, particle board, and both oak and pine plywood. Class B woods usually include spruce, western hemlock, and western red cedar. For comparison, brick, gypsum, fiber cement board, and FRT plywood have a Class A rating.

It is important that this testing is completed by 3rd party labs like ICC, UL, or other IAS accredited institutions. This is the only valid way to establish the fire rating of wood as it pertains to flame spread and smoke development.

Wood can be further tested as part of a fire rated structural assembly, for longer fire endurance ratings. This test, known as ASTM E119, UL 263, or CAN ULC S101 tests wall and floor/ceiling construction. The fire endurance rating test can last from anywhere between 1-4 hours should say from anywhere between 1-2 hours.

It is important to note that this standard tests the performance of the horizontal or vertical assembly as a whole, and may include other substrates. The rating is achieved over the entire assembly and is not specific to the individual components.

Chapter 16 of the American Wood Council’s National Design Specification® (NDS®) for Wood Construction highlights detailed formulas to guide proper fire rating on wood structures. The existing fire rating in a wooden construction can be demonstrated by following these guidelines closely. This can be helpful for trying to build a rating around existing and/or exposed wood members.

The aim of fireproofing wood is to slow down rates of ignition, prolong the integrity of the structures, and to lower the heat that is naturally released during wood combustion.

Five strategies have been highlighted to improve fireproofing performance on wood.

- Redirecting pyrolysis: Fire retardants can be used to change the pathway of pyrolysis in wood. This is a relatively quick and inexpensive method. Fire retardants are a chemical treatment for a substrate that can be used to slow down the spread of fire across a substrate. This includes wood.

- Insulating Layers: Insulating layers can help slow the natural destructive reaction of wood when exposed to heat. An example of an insulating layer would be an intumescent coating which expands as it is exposed to heat causing a thorough layer that will significantly prolong the protection of wood. This method is very effective but can be expensive and also covers the natural aesthetic of wood.

- Changing Thermal Properties: If you manipulate the thermal properties of wood this has the potential to make it more resistant to burning. For example, by making wood wet one is manipulating the thermal properties of wood. As the water is heating up and evaporating on the wood the water is consuming the heat, and inadvertently delaying the transfer of heat across a wood structure.

- Adding Thermal Inertia: Some attempts have been made to fireproof wood by adding components with higher thermal inertia to wood assemblies. Metal layers may be used to accomplish this however large amounts of metal are needed to accomplish this goal which can increase the cost and weight of the structure.

- Noncombustible Gasses: Some fire retardants can release noncombustible gases, for example, water vapor, which in turn slow the degradation of the wood they are protecting.

Fire resistant coatings are becoming more and more advanced and offer a reliable solution for increasing the fire rating on wood.

Intumescent coatings are often regarded as a smart and effective approach to fireproofing substrates including wood. Fire retardants are similarly a valid option. While they typically offer more limited protection than their intumescent cousins, they offer other diverse benefits.

Regardless of your project, FlameOFF Coatings has a wood product that can help. We offer both a thin film intumescent coating and a clear fire retardant treatment compatible with wood! Learn more about your options here.

Contact our highly informed technical support staff with any further questions on this subject.