Protecting steel structures with intumescent fireproofing is critical to meeting building code and safety requirements.

The ICC-ESL-1191 report provides essential data on how much coating is needed for various steel member types. However, to make the most of this information, you need to know how to read the tables and understand section factors.

This guide will walk you through how to do just that.

- •Confirm Your Project Aligns With Relevant Testing Standards

- •Understand Why Steel Size Affects Intumescent Coating Thickness

- •What is the Steel Section Factor?

- •Determine Your Steel's Section Factor

- •Understanding Exposure Types

- •Match Section Factor to ICC ESL Table

- •Know Why Steel Coverage Calculator Values Might Vary Slightly

- •Final Notes and Resources

Confirm Your Project Aligns With Relevant Testing Standards

Before diving into the data tables, review Page 1 of the ICC-ESL-1191 report. This page identifies the test standards (such as ASTM E119, UL 263, etc.) under which the product was evaluated.

Ensure these standards align with the fire resistance requirements of your specific project.

Understand Why Steel Size Affects Intumescent Coating Thickness

When planning your steel fireproofing, remember: bigger steel doesn’t necessarily mean more intumescent coating.

The key variable is the Section Factor, which captures how much surface area (per unit mass) is exposed to fire. More surface area relative to mass means the steel heats up faster, requiring a thicker coating.

The Steel Section Factor is an industry-standard measurement, commonly expressed as one of the following ratios depending on region and steel type:

- W/D (Weight/Heated Perimeter)

- A/P (Cross-Sectional Area / Heated Perimeter)

- Hp/A (Heated Perimeter / Cross-Sectional Area)

These values are standardized, meaning a W12x45 beam will typically have the same W/D ratio (~0.82 for 4-sided exposure) regardless of the supplier.

However, your bill of material or other project-specific documents may not display this information, which can cause difficulty interpreting the necessary mil thickness recommendation in a 3rd party listing report.

Learn more about steel section factor in our article: Why the Size of Steel Is Important in Fireproofing

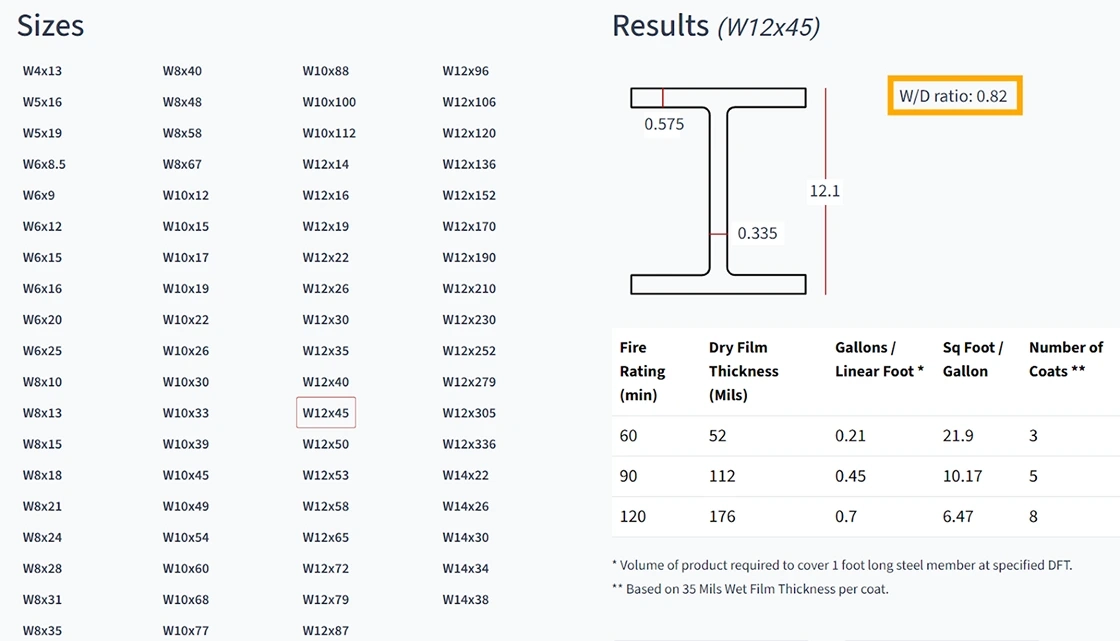

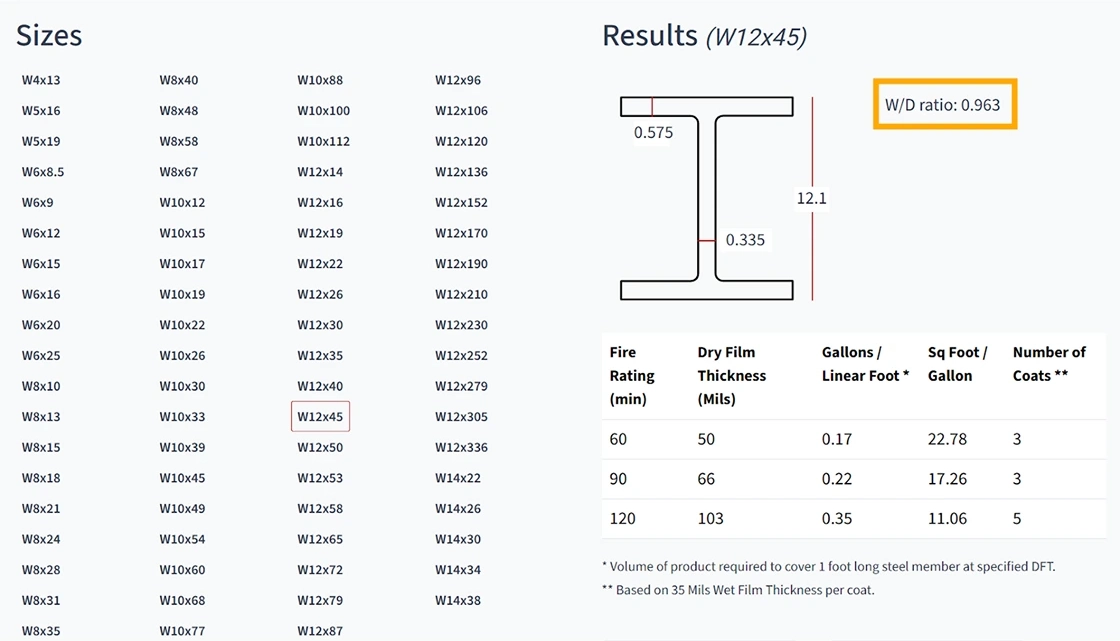

Your project documents might not list section factors directly. In that case, use our FlameOFF Steel Coverage Calculator. Simply select your steel size and usage type (beam or column), and the calculator will display the Section Factor.

You’ll see the Section Factor noted in the top right corner, like this:

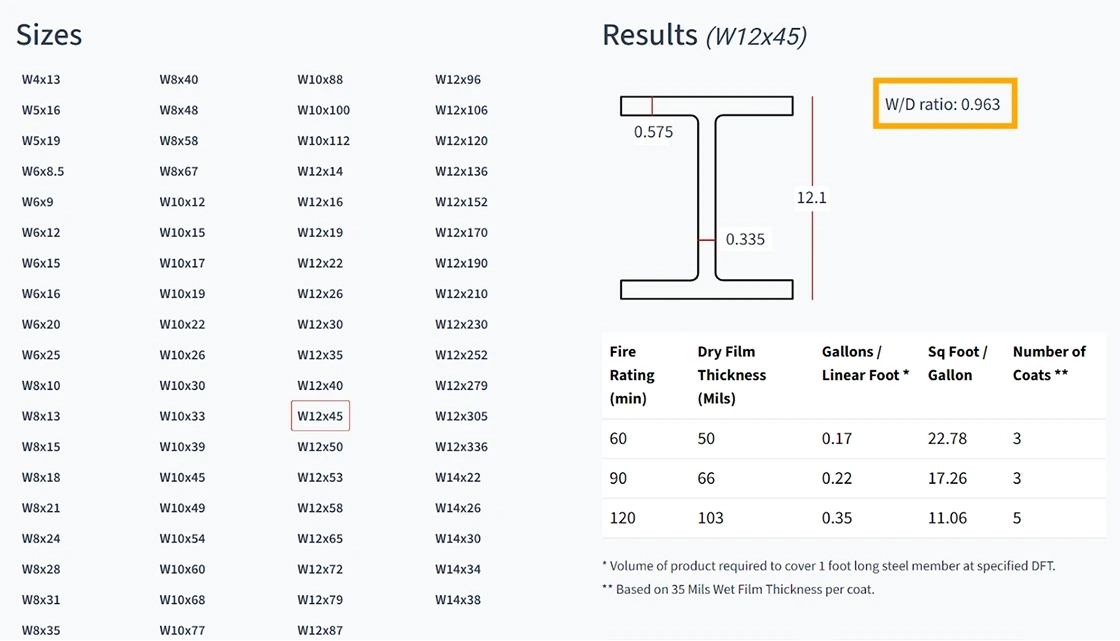

It is important to note that the section factor changes when the steel exposure changes. For example:

- Column (4-sided exposure): All sides are exposed to fire.

- Beam (3-sided exposure): One side (typically the top) is protected by a slab or deck.

This exposure affects the heated perimeter, which in turn changes the Section Factor.

Example: You can see this displayed in our steel coverage calculator images, where column use is selected, and W/D is 0.82, and below, where beam use is selected, and W/D is 0.96.

Read the article Why the Size of Steel Is Important in Fireproofing for more details.

You can also find Steel Section Factor values published all across the web, in professional texts, direct from steel manufacturers, etc. Let’s move on to looking at how you use this info!

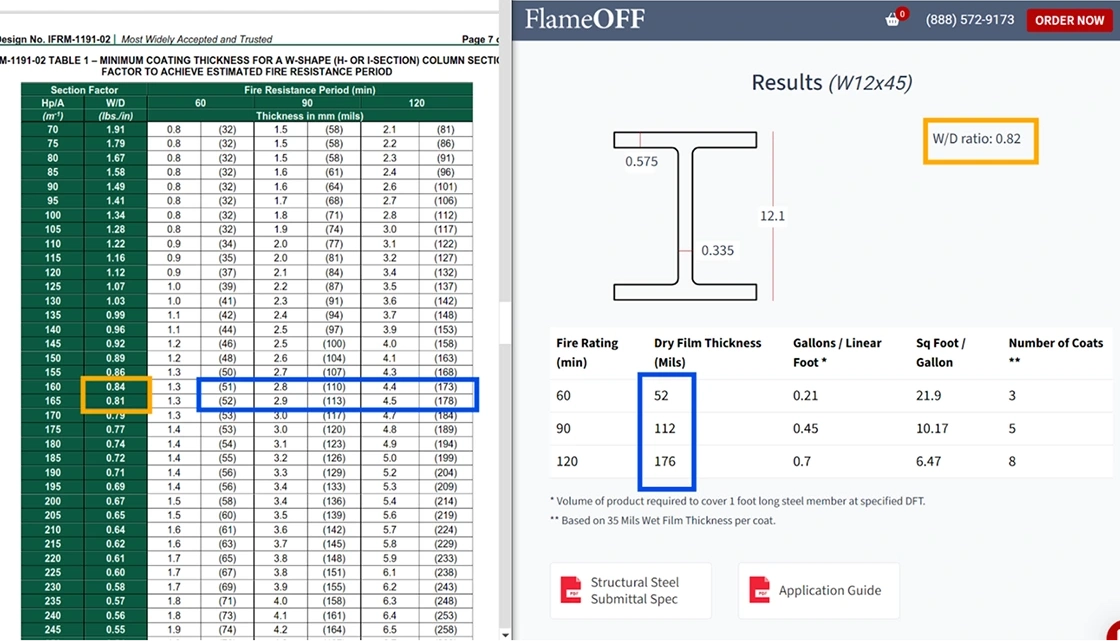

Once you know your Section Factor, it’s time to read the ICC-ESL-1191 report:

- Identify the appropriate table based on your steel type (wide flange (W) columns, beams, hollow steel sections, etc.).

- In the left-hand column, find the range that includes your Section Factor.

- Follow the row to the right to find the recommended mil thickness for your desired fire rating (e.g., 1 hour, 2 hour).

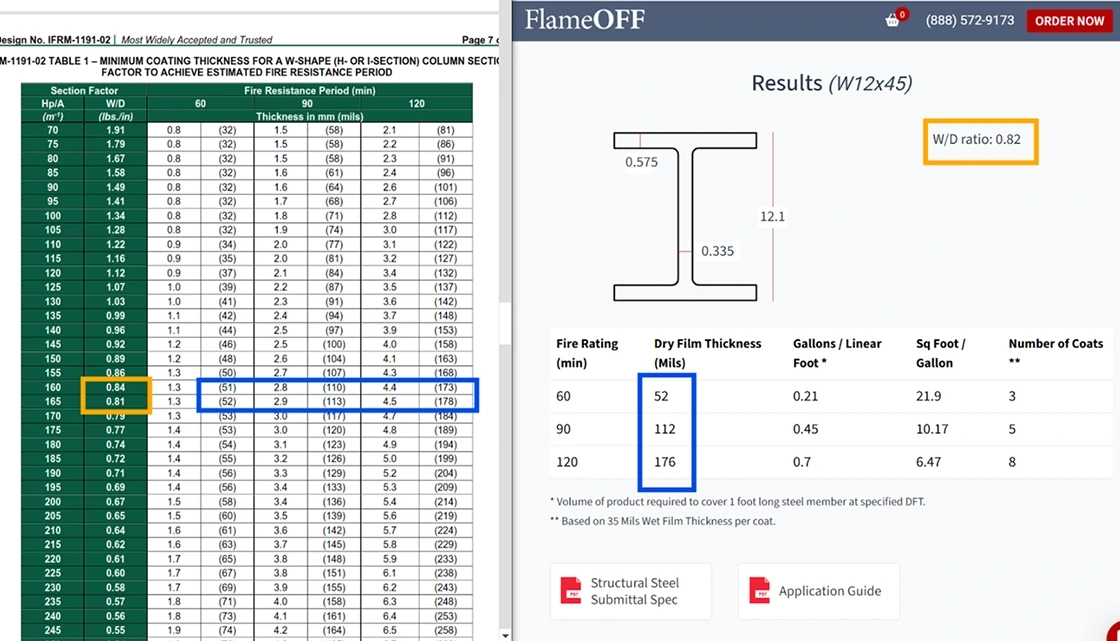

If your steel is W12x45 with a W/D ratio of 0.82:

- Go to the table for W-shapes.

- Find the row with W/D = 0.82. The W/D ratio (highlighted in orange) falls between two numbers on the listing table.

- To the right, we see the recommended mil thicknesses, highlighted in blue.

Both the ICC report and our Steel Coverage calculator will provide you with the same information for determining mil thickness; however, understanding how to read the 3rd-party listing table when specifying the product and obtaining approval for its use in your project is important.

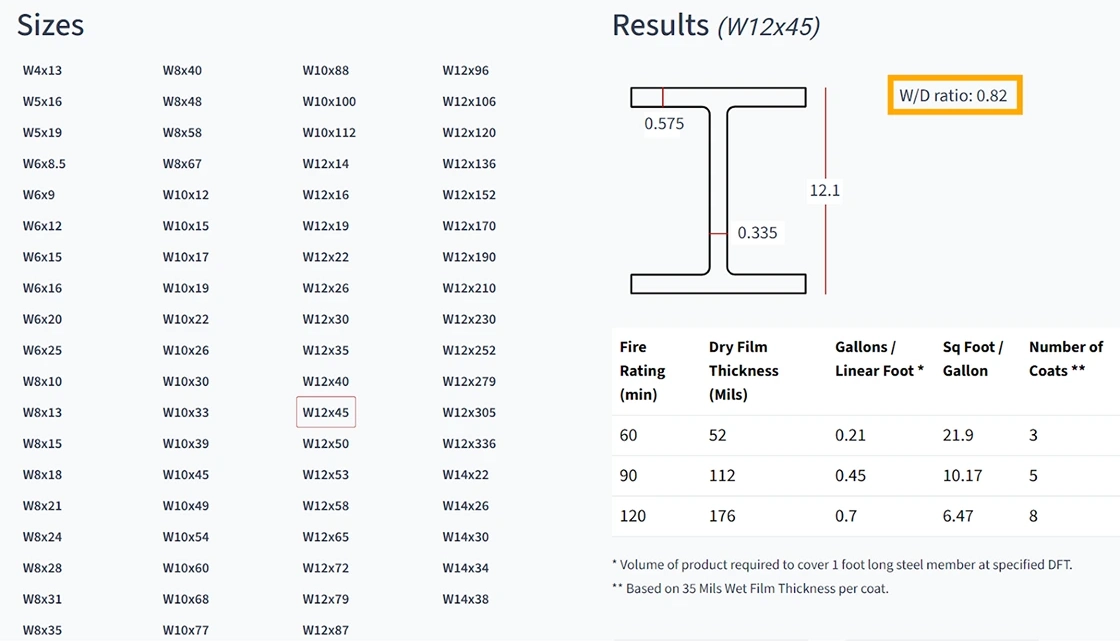

Values Might Vary Slightly

There may be minor discrepancies between the mil thickness listed in the ICC report and those shown in our Steel Coverage Calculator. That’s because the calculator incorporates test data from both ICC and UL testing for a more comprehensive testing profile. Remember, Fire Barrier Paint is both UL and ICC listed for structural steel applications!

- Bookmark our calculator: Steel Coverage Calculator

- Read more about Section Factors: Why Steel Size Matters

- Have questions? Reach out to our technical team for expert guidance.

Understanding how to interpret third-party fireproofing data empowers you to specify products accurately, streamline approvals, and build safer structures.

Interpreting ICC-ESL-1191

(insert info about reviewing page 1 to confirm relevant test standards for project)

When planning your steel project, it’s important to understand that the size of the steel impacts the required mil thickness of the intumescent coating that will protect it.

The relationship between the steel size and the required coating thickness is dependent upon the steel’s measure of mass (also known as Section Factor, and usually displayed as a ratio of W/D, A/P, or Hp/A, depending upon the type of steel, and your location, where W, D, A, P, etc are values that represent the steel’s heated perimeter, weight, etc.).

You can read more about Steel Section Factors here: https://flameoff.com/why-the-size-of-steel-is-important-in-fre-proofing.

Steel Section Factors are industry standard values that should be uniform across steel suppliers. For example, a W12x45 piece of steel should have a W/D ratio of ~0.82 (for 4 sided vertical exposure) across all suppliers.

However, your bill of material or other project-specific documents may not display this information, which can cause difficulty interpreting the necessary mil thickness recommendation in a 3rd party listing report. These listing reports typically showcase tested mil thicknesses in relation to Section Factor (ie 0.82), not steel designation (ie W12x45).

Our FlameOFF Steel Coverage Calculator displays the steel’s Section Factor value when you click each size.

You can access our calculator here: https://flameoff.com/steel-coverage-calculator.

You’ll see the Section Factor noted in the top right corner, like this:

*Important note: The Section Factor changes when the steel exposure changes.

For example, a wide flange section used as a column will typically have 4-sided exposure- meaning all 4 sides will be exposed and require intumescent coating. A wide flange section used as a beam will typically have 3-sided exposure, where the top of the beam is covered by the floor or roof deck, and will not require intumescent paint.

This exposure changes the heated perimeter value, which in turn changes the calculated value of the Section Factor. You can read more about this in the article about Steel Section Factor referenced above. You can see this displayed in our steel coverage calculator images above (where column use is selected, and W/D is 0.82) and below (where beam use is selected, and W/D is 0.96).

You can also find Steel Section Factor values published all across the web, in professional texts, direct from steel manufacturers, etc. Let’s move on to looking at how you use this info!

To match this information to our ICC Listing Table of published mil thickness recommendations, start with your steel designation (size), determine the Section Factor, then scroll to the appropriate table in the 3rd party listing report, which is broken out by steel type. Find the Section Factor you are working with in the left hand column, then follow the table to the right for the recommended mil thickness for the required rating.

Let’s take the example we used before, W12x45, and take a look. We see that the W/D ratio (highlighted in orange) falls between two numbers on the listing table. To the right, we see the recommended mil thicknesses, highlighted in blue. Both resources will provide you the same information for determining mil thickness, but it is important to understand how to read the 3rd party listing table when it comes to specifying the product and having it approved for use in your project.

Please note that there are some cases where the recommended mil thickness in our Steel Coverage Calculator may differ slightly from the recommended thickness in the ESL report. This occurs because our Steel Coverage Calculator factors in both our UL and ICC testing data for a custom calculation. The differences are minor and supported by testing from one or both of these major testing organizations. Should you ever have questions or concerns, please reach out to our technical team for assistance!